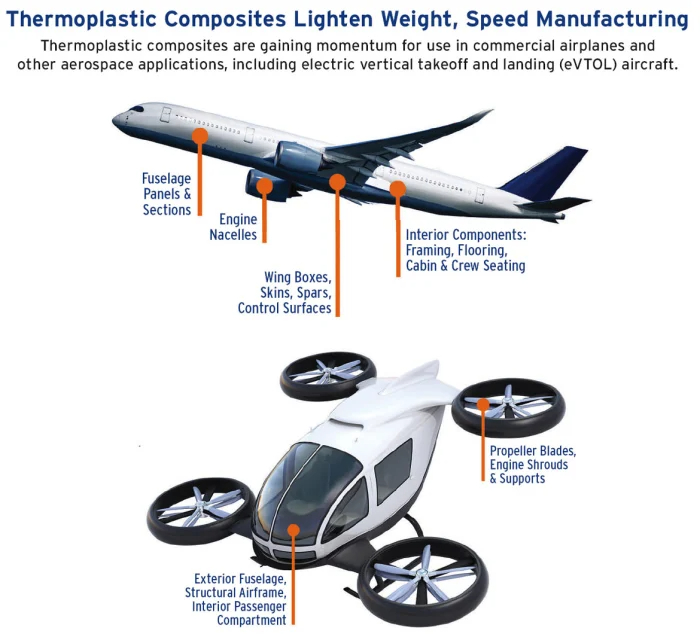

Lilemong tsa morao tjena, ho bile le tsoelo-pele e potlakileng ea fiber-reinforcedmetsoako ea thermoplastic ka li-resin tsa thermoplastic joalo ka matrix, 'me ho na le keketseho ea lipatlisiso le nts'etsopele ea likarolo tsena tse sebetsang hantle lefatšeng ka bophara. Thermoplastic composite ke metsoako e entsoeng ka lipolyme tsa thermoplastic tse kang polyethylene (PE), polyamide (PA), polyphenylene sulfide (PPS), polyetherimide (PEI), polyether ketone (PEKK) le polyether ether ketone (PEEK) e le matrix le tse fapa-fapaneng tse tsoelang pele / tse sa khaotseng. likhoele (mohlala, likhoele tsa khabone, likhoele tsa khalase, likhoele tsa aramid, jj.

Thermoplastic grease-based composite haholo-holo ke Long Fiber reinforced Thermoplastics (LFT), MT e tsoelang pele ea litheipi tse kenngoeng esale pele le 'mete oa khalase o matlafalitsoeng Thermoplastics(CMT).

Ho ea ka tšebeliso ea litlhoko tse fapaneng, matrix a resin a na le PPE.PAPRT, PELPCPES, PEEKPI, PA le li-plastiki tse ling tsa thermoplastic engineering.

Matrix a Thermoplastic

Thermoplastic matrix ke mofuta oa thepa ea thermoplastic e nang le thepa e ntle ea mochini le ho hanyetsa mocheso e ka sebelisoang mefuteng e mengata ea lihlahisoa tsa indasteri. Thermoplastic matrix e na le matla a phahameng, ho hanyetsa mocheso le ho hanyetsa ho hotle ha kutu.

Li-resin tsa thermoplastic tse sebelisoang hona joale lits'ebetsong tsa aerospace haholo-holo li-matrices tse nang le mocheso o phahameng, tse sebetsang hantle haholo, ho kenyeletsoa PEEK, PPS le PEI, tseo PEI ea amorphous e sebelisoang haholo lits'ebetsong tsa sefofane ho feta semi-crystalline PPS le PEEK, tseo PEI ea amorphous. e na le lits'ebetso tse ngata meahong ea lifofane ho feta semi-crystalline PPS le mocheso o phahameng oa ho bopa PEEK ka lebaka la mocheso oa eona o tlase oa ts'ebetso le litšenyehelo tsa ho sebetsa.

Li-resin tsa thermoplastic li na le thepa e ntle ea mochini le ho hanyetsa lik'hemik'hale, mocheso o phahameng oa ts'ebeletso, matla a phahameng a khethehileng le ho thatafala, ho thatafala ha fracture le mamello ea tšenyo, ho hanyetsa mokhathala o matla, bokhoni ba ho bopa li-geometri le meaho e rarahaneng, ho feto-fetoha ha mocheso oa mocheso, ho sebelisoa hape, botsitso bo botle libakeng tse thata. , ho bōptjoa ho ka phetoa, le ho cheseha, joalo-joalo.

Likopano e entsoeng ka resin ea thermoplastic le lisebelisoa tse matlafatsang li na le melemo e mengata e kang ho tšoarella, ho ba thata haholo, ho hanyetsa tšusumetso e matla le mamello ea tšenyo; fiber prepreg ha e hloke ho bolokoa mocheso o tlase hape, nako e sa lekanyetsoang ea polokelo ea prepreg; khutšoanyane bōpa potoloho, weldable, phahameng tlhahiso, ho le bonolo ho lokisa; matlakala a ka sebelisoa hape le ho sebelisoa hape; tokoloho e kholo ea moralo oa sehlahisoa, e ka etsoa ka libopeho tse rarahaneng, ho ikamahanya le sebopeho se pharaletseng, joalo-joalo.

Lintho tse matlafatsang

Ka kakaretso, bolelele ba likhoele tse matlafalitsoeng tse khuts'oane ke 0.2 ho 0.6 mm, 'me kaha likhoele tse ngata li ka tlase ho 70 μm ka bophara, kahoo likhoele tse khutšoane li shebahala joalo ka phofo. Fiber e khuts'oane e matlafalitsoeng ka thermoplastic hangata e etsoa ka ho kopanya likhoele hore e be thermoplastic e qhibilihisitsoeng. Bolelele le mokhoa o sa reroang oa likhoele tse ka har'a matrix li etsa hore ho be bonolo ho fihlella ho koloba hantle, 'me likhomphutha tse khutšoane tsa likhoele ke tsona tse bonolo ho etsoa ha li bapisoa le lisebelisoa tse matlafalitsoeng tsa fiber e telele le e tsoelang pele, empa ka ntlafatso e nyane haholo ea thepa ea mochini. Li-composites tsa fiber tse khutšoane li atisa ho etsoa likarolo tsa ho qetela ka mokhoa oa ho bopa kapa oa extrusion hobane likhoele tse khutšoanyane li na le tšusumetso e fokolang ho phallo.

Li-composites tse matlafalitsoeng ka fiber e telele hangata li ka ba bolelele ba limilimithara tse 20 'me hangata li lokisoa ho sebelisoa likhoele tse sa khaotseng tse kenngoeng ka resin ebe li khaola ho ea bolelele bo itseng. Mokhoa o sebelisoang ka tloaelo ke mokhoa oa ho bopa oa pultrusion, oo ho oona ho tsoelang pele ha motsoako oa likhoele le resin ea thermoplastic ho hlahisoang ka ho otlolla likhoele ka mochini o khethehileng oa ho bopa. Hajoale, likhomphutha tse telele tse matlafalitsoeng ka fiber ea PEEK thermoplastic li ka fihlela thepa ea sebopeho sa MPa e fetang 200 ka khatiso ea FDM le modulus e fetang 20 GPa, ka ts'ebetso e ntle ka ho bopa ente.

Likhoele tse ka har'a li-composites tse matlafalitsoeng ka fiber li "tsoelapele" 'me li bolelele ba limithara tse' maloa ho isa ho tse likete tse 'maloa. Li-composites tsa fiber tse tsoelang pele hangata li fumaneha e le li-laminate, litheipi tsa prepreg, kapa li-braids, tse entsoeng ka ho kenya matrix a thermoplastic a lakatsehang ka likhoele tse tsoelang pele.

Ke litšobotsi life tsa lisebelisoa tse kopantsoeng tse matlafalitsoeng ka likhoele?

Li-composite tse matlafalitsoeng ke likhoele tse entsoeng ka mokhoa oa ho tsoelipana, ho bopa kapa ho pultrusion ho matlafatsa lisebelisoa tsa fiber, joalo ka fiber ea khalase, fiber ea carbon, fiber ea aramid, joalo-joalo, le thepa ea matrix. Ho ea ka lisebelisoa tse fapaneng tse matlafatsang, metsoako e tloaelehileng ea fiber e matlafalitsoeng e arotsoe ka likhalase tse matlafalitsoeng ka khalase (GFRP), carbon fiber reinforced composite (CFRP) le aramid fiber reinforced composite (AFRP).

Ka lebaka la litšobotsi tse latelang tsa likhomphutha tse matlafalitsoeng ke fiber:

(1) matla a phahameng le modulus e phahameng;

(2) sebopeho sa thepa ea thepa;

(3) khanyetso e ntle ea kutu le ho tšoarella;

(4) coefficient ea katoloso ea mocheso e tšoanang le ea konkreite.

Litšobotsi tsena li etsaLisebelisoa tsa FRPe ka fihlela litlhoko tsa meaho ea sejoale-joale ho isa bolelele bo boholo, tora e telele, mojaro o boima, boima bo bobebe le matla a phahameng, le ho sebetsa tlas'a maemo a thata, hape e fihlela litlhoko tsa nts'etsopele ea kaho ea meaho ea sejoale-joale ea liindasteri, kahoo e sebelisoa haholo le ho feta. meahong e fapaneng ea sechaba, marokho, litsela tse kholo, likepe, meaho ea hydraulic le meaho e ka tlas'a lefatše.

tlanya monabakeng sa tlhahisoleseding e eketsehileng mabapi le lisebelisoa tse kopantsoeng kaGRECHO Fiberglass

Nako ea poso: Mar-31-2023