Kakaretso

Nakong e fetang halofo ea lekholo la lilemo, lisebelisoa tse entsoeng ka fiber tse matlafalitsoeng li 'nile tsa sebelisoa haholo ka lebaka la thepa ea tsona e babatsehang,' me karolo ea bohlokoa ea ho matlafatsa likhoele ka thepa e kopantsoeng e iponahatsa. Ho tloha ha ho fihlalintho tse entsoeng ka motsoako, likhoele tse matlafatsang li bile le phetoho ho tloha ho likhoele tsa tlhaho ho ea ho likhoele tsa maiketsetso.

Hajoale, likhoele tse matlafatsang tse atileng haholo li kenyelletsa likhoele tsa khalase, likhoele tsa aramid,likhoele tsa carbon, joalo-joalo Sehlooho sena se tla hlahisa litšobotsi le tšebeliso ea likhoele tsa khalase bakeng sa ho matlafatsa motsoako.

Ke engfiberglass?

Likhoele tsa khalase li sebelisoa haholo ka lebaka la theko e tlaase le thepa e ntle, haholo-holo indastering ea metsoako. Khale koana lekholong la bo18 la lilemo, Maeurope a ile a hlokomela hore khalase e ka ohloa hore e be likhoele bakeng sa ho loha. Lekese la Moemphera oa Fora Napoleon le ne le se le ntse le e-na le masela a khabisitsoeng a entsoeng ka fiberglass. Likhoele tsa khalase li na le likhoele le likhoele tse khutšoane kapa li-flocs. Li-filaments tsa khalase li atisa ho sebelisoa ka thepa e entsoeng ka motsoako, lihlahisoa tsa rabara, mabanta a conveyor, li-tarpaulins, joalo-joalo. Likhoele tse khutšoanyane li sebelisoa haholo-holo ho li-feelings tse sa lohiloeng, li-plastiki tsa boenjiniere le lisebelisoa tse kopantsoeng.

Lits'ebetso tse khahlang tsa 'mele le mochini oa fiber, bonolo ho e etsa, le litšenyehelo tse tlase ha li bapisoa le fiber ea khabone li e etsa khetho bakeng sa lits'ebetso tse kopaneng tse sebetsang hantle. Likhoele tsa khalase li entsoe ka li-oxide tsa silica. Likhoele tsa khalase li na le lisebelisoa tse ntle tsa mochini tse joalo ka ho se brittle, matla a phahameng, ho satalla ho tlase le boima bo bobebe.

Li-polymers tse matlafalitsoeng ka khalase li na le sehlopha se seholo sa mefuta e fapaneng ea likhoele tsa khalase, joalo ka likhoele tsa longitudinal, likhoele tse khaotsoeng, meseme e lohiloeng ledimmete tse sehiloeng , 'me li sebelisetsoa ho ntlafatsa thepa ea mechine le ea tribological ea metsoako ea polymer. Likhoele tsa khalase li ka fihlela likarolo tse phahameng tsa mantlha, empa bofokoli bo ka etsa hore likhoele li robehe nakong ea ts'ebetso.

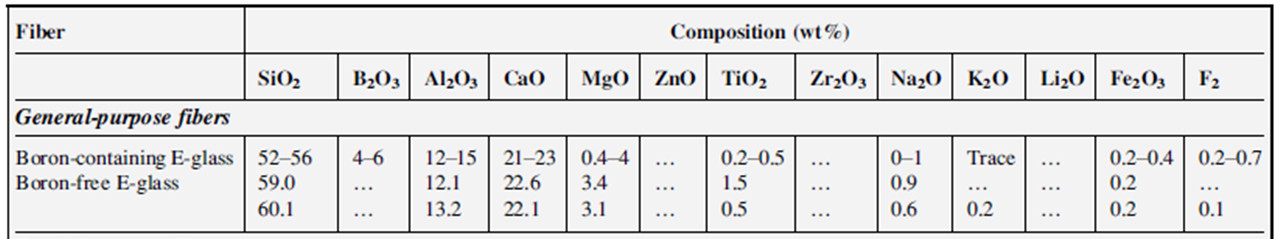

Tafole e latelang e bonts'a mefuta e fapaneng ea likhoele tsa khalase le metsoako:

Lisebelisoa tsa Glass Fiber

Litšobotsi tse ka sehloohong tsa fiber ea khalase li kenyelletsa lintlha tse latelang:

Ha ho bonolo ho monya metsi: Fiber ea khalase e thibela metsi 'me ha e tšoanelehe bakeng sa liaparo, hobane mofufutso o ke ke oa kenngoa, o etsa hore ea apereng a ikutloe a le metsi; hobane thepa ha e amehe ke metsi, e ke ke ea fokotseha.

In-elasticity: Ka lebaka la ho haella ha elasticity, lesela ha le na ho otlolla le ho hlaphoheloa ha tlhaho. Ka hona, ba hloka phekolo ea holim'a metsi ho hanela ho sosobana.

Matla a Phahameng: Fiberglass e matla haholo, e batla e le matla joalo ka Kevlar. Leha ho le joalo, ha likhoele li hohlana, lia robeha ’me li etsa hore lesela le be le ponahalo e shaggy.

Insulation:Ka mokhoa o mokhuts'oane oa fiber, fiberglass ke insulator e ntle haholo.

Drability:Likhoele li hohla hantle, li etsa hore e be tse loketseng likharetene.

Ho hanyetsa Mocheso:Likhoele tsa khalase li na le mocheso o phahameng oa mocheso, li ka mamella mocheso ho fihlela ho 315 ° C, ha li amehe ke letsatsi, bleach, baktheria, hlobo, likokoanyana kapa alkalis.

E ka etsahala: Likhoele tsa khalase li angoa ke hydrofluoric acid le hot phosphoric acid. Kaha fiber ke sehlahisoa se entsoeng ka khalase, likhoele tse ling tse tala tsa khalase li lokela ho sebetsoa ka hloko, joalo ka lisebelisoa tsa ntlo, hobane likhoele tsa fiber li fokola 'me li ka phunya letlalo, kahoo li-gloves li lokela ho apesoa ha u tšoara fiberglass.

Lintho tsa 'mele le tsa mochini tsa likhoele tse tloaelehileng tsa khalase tsa khoebo li bonts'oa tafoleng e ka tlase:

Glass Fiber Manufacturing process

Glass fiber ke fiber e seng ea tšepe eo hajoale e sebelisoang haholo joalo ka thepa ea indasteri. Ka kakaretso, lisebelisoa tsa mantlha tsa fiber ea khalase li kenyelletsa liminerale tse fapaneng tsa tlhaho le lik'hemik'hale tse entsoeng ke batho, likarolo tsa mantlha ke lehlabathe la silika, limestone le molora oa soda.

Silica sand e sebetsa joalo ka khalase ea pele, ha molora oa soda le lejoe la mokoetla li thusa ho theola mocheso o qhibilihang. Coefficient e tlase ea katoloso ea mocheso e kopantsoeng le conductivity e tlase ea mocheso ha e bapisoa le asbestos le li-organic fibers li etsa hore fiberglass e be thepa e tsitsitseng e khonang ho qhala mocheso kapele.

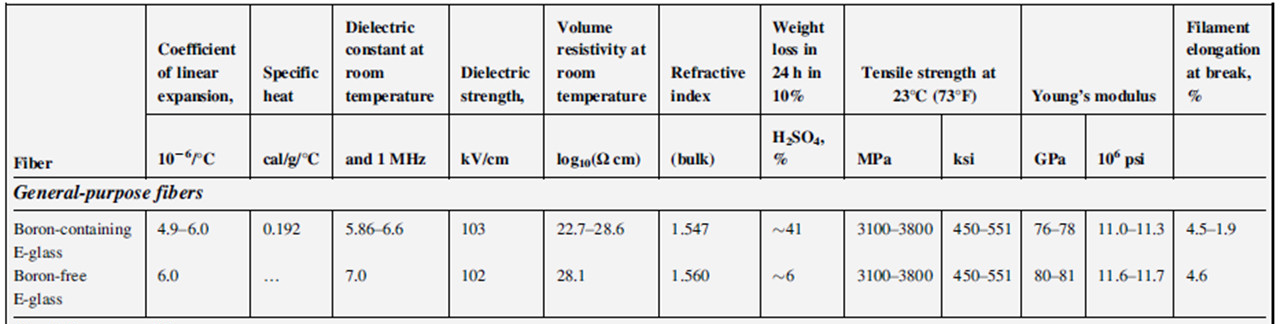

Glass Fiber Manufacturing Process Flow Chart

Likhoele tsa khalase li hlahisoa ke ho qhibiliha ka ho toba, ho kenyelletsang mekhoa e kang ho kopanya, ho qhibiliha, ho ohla, ho roala, ho omisa le ho paka. Sehlopha ke boemo ba pele ba tlhahiso ea likhalase, moo lisebelisoa tse ngata li kopantsoeng ka ho feletseng, 'me motsoako o tšeloa ka sebōping bakeng sa ho qhibiliha mocheso o phahameng oa 1400 ° C. Mocheso ona o lekane ho fetola lehlabathe le lisebelisoa tse ling hore e be ho qhibiliha; khalase e qhibilihisitsoeng ebe e phalla ka har'a sehloeki 'me mocheso o theohela ho 1370°C.

Nakong ea ho ohloa ha likhoele tsa khalase, khalase e qhibilihisitsoeng e tsoa ka letsoho e nang le masoba a matle haholo. Letlapa la liner le futhumatsoa ka elektronike 'me mocheso oa eona o laoloa ho boloka viscosity e sa feleng. Sefofane sa jete sa metsi se ile sa sebelisoa ho pholisa khoele ha se tsoa ka letsoho mochesong o ka bang 1204°C.

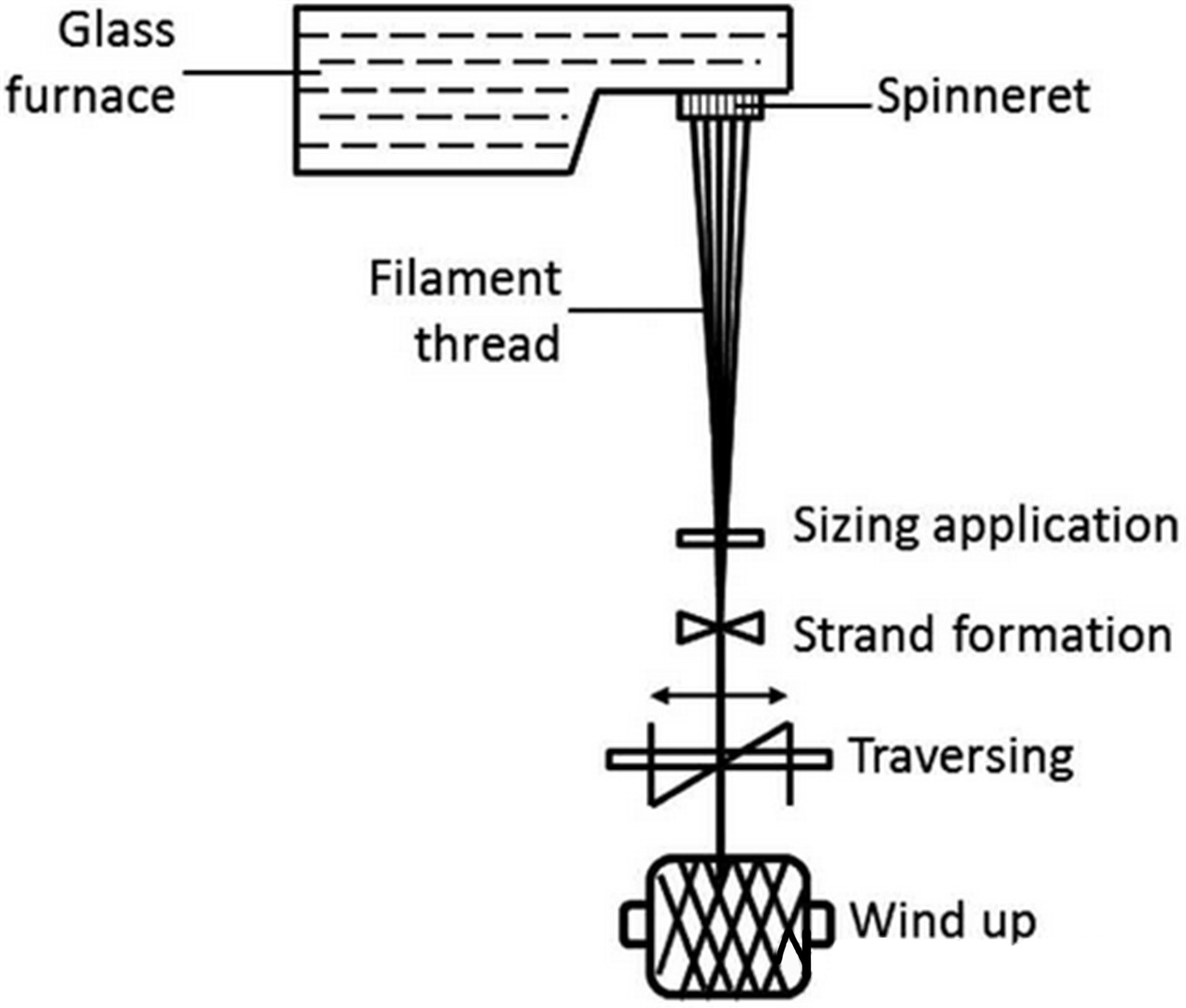

SekemaDsetšoantšo saGngoananaFiberSpinning

Molapo o pharalletseng oa khalase e qhibilihisitsoeng o huleloa ka mokhoa oa mochini ka har'a likhoele tse nang le bophara ho tloha ho 4 μm ho isa ho 34 μm. Tsietsi e fanoa ho sebelisoa moea o fefohang ka lebelo le phahameng 'me khalase e qhibilihisitsoeng e huleloa ka har'a likhoele. Sethaleng sa ho qetela, litlolo tsa lik'hemik'hale tsa litlolo, li-binders le li-coupling agents li sebelisoa ho li-filaments. Lubrication e thusa ho sireletsa likhoele hore li se ke tsa khoptjoa ha li ntse li bokelloa ebe li kenngoa ka har'a liphutheloana. Ka mor'a hore ho be le boholo, likhoele li omisoa ka ontong; joale likhoele li se li loketse ho sebetsoa hape hore e be likhoele tse khaotsoeng, li-rovings kapa likhoele.

Kopo eaGngoananaFiber

Fiberglass ke thepa ea tlhaho e sa cheng 'me e boloka hoo e ka bang 25% ea matla a eona a pele ho 540 ° C. Lik'hemik'hale tse ngata li na le phello e fokolang holim'a likhoele tsa khalase. Inorganic fiberglass e ke ke ea bōptjoa kapa ea senyeha. Likhoele tsa khalase li angoa ke hydrofluoric acid, hot phosphoric acid le lintho tse matla tsa alkaline.

Ke sesebelisoa se setle sa insulating ea motlakase. Masela a fiberglass a na le thepa e kang ho monya mongobo o tlase, matla a phahameng, ho hanyetsa mocheso le dielectric kamehla, e leng se etsang hore e be li-reinforcement tse loketseng bakeng sa liboto tsa potoloho tse hatisitsoeng le li-varnish tse sireletsang.

Karo-karolelano e phahameng ea matla ho boima ba fiberglass e etsa hore e be thepa e ntle haholo bakeng sa lits'ebetso tse hlokang matla a phahameng le boima bo fokolang. Ka mokhoa oa masela, matla ana a ka ba a sa tšoaneng kapa a mabeli, a lumella ho feto-fetoha ha moralo le litšenyehelo bakeng sa mefuta e mengata ea likopo 'marakeng oa likoloi, kaho ea sechaba, thepa ea lipapali, sefofane, marine, lisebelisoa tsa elektronike, Matla a Lehae le a moea.

Li boetse li sebelisoa ha ho etsoa li-composite tsa meralo, liboto tsa potoloho tse hatisitsoeng le lihlahisoa tse fapaneng tsa morero o khethehileng. Tlhahiso ea selemo le selemo ea faeba ea likhalase lefatšeng e ka ba lithane tse limilione tse 4,5, 'me bahlahisi ba ka sehloohong ke Chaena (karolo ea 60% ea mmaraka), United States le European Union. (Mohloli: Carbon Fiber le Theknoloji ea eona e Kopanetsoeng ea Material)

Sheba pokello ea rona ea lifoto le litaba tse ling mabapi le linyeoe tsa fiber ea khalase ea GRECHOMona.

Whatsapp: +86 18677188374

Lengolo-tsoibila: info@grechofiberglass.com

Mohala: +86-0771-2567879

Mob.: +86-18677188374

Webosaete:www.grechofiberglass.com

[Tlhahiso e hatisitsoeng]: Tokelo ea litokelo tsa lingoliloeng tse hlahisitsoeng ke ak'haonte ena ea semmuso ke ea mongoli oa mantlha, 'me ho lateloa polelo ea mongoli oa mantlha. Haeba mongolo oa mantlha o sena polelo ea litokelo, re tla latela molao-motheo oa hajoale oa ho bula Marang-rang ntle le ho tsebisa mongoli. Hatisa sengoloa se ka tlase hape. Haeba khatiso e ncha e sa lumellane le polelo ea litokelo tsa mongoli kapa mongoli ha a lumele ho hatisa hape, ka kopo ngolla ho re tsebisa 'me re tla sebetsana le eona kapele kamoo ho ka khonehang.

Nako ea poso: Jul-21-2021